Well, in between another 85mm, building flat pack laundry’s in Castlemaine, and reducing the handicap down to 16 the shed is slowly taking shape.

First to go on were the walls followed by the strapping and then the roof.

Editors note: Roller doors are extremly heavy, limiting the number of times you lift them up and down is a necessity. Also, you should check to ensure you have your roller doors the right way around before cutting anything. Although this school boy mistake did not result in me knocking on the finance ministers door asking for another roller door I was only about 40mm away from needing to.

Speaking off the finance minister, working late into the evening is accepted behaviour, yet no site lights have been provided at this point in time. With one week remaining of daylight savings time is running out fast.

The working at heights policy was passed around at smoko, I think some of the guys read it, this one didn't as I don't even think he has his chinese workboots on. I think I got the last sheet on before the 85mm came this day.

Flashing and gutters to be finished before the concrete goes in. The gas bottle has been filled, table tennins table wiped down, and the GC has sent the robe off to the dry cleaners for the big opening - let the shed times roll.

On the 27th of November 2010 Kate Maree Andronescu Married Simon Luke Guthrie. From this day forth the happy couple embarked on a mission to build a shed. This blog tells their story.

Sunday, March 27, 2011

Sunday, March 13, 2011

Back on the Job

Day two and Hobie was on hand first thing. Although Hobie brought a lot to the table I've had to charge his parents for all the dirt that he ate whilst on the job. Red loam is not cheap.

After another "Classic" Simon and Dale error the team started to recover some of the four hours lost. Slowly the frame took shape infront of the massive crowd that was keen to be part of the big occasion.

I'm really still amazed that no one was injured during this consturction given the primitive methods used. I would have it no other way.

A big thanks to Briggsy and Sheers who turned up to work on the Saturday to get things moving. A special mention to Briggsy for falling off the first ladder he climbed up, once I told him there was no work cover he dusted himslef off and got on with it. This did however mean I needed to send the finance minister off for more supplies to enusure our thirst was satisfied at the end of the day.

The end result is the frame was completed by Saturday evening in readiness for the sheeting and roofing.

After another "Classic" Simon and Dale error the team started to recover some of the four hours lost. Slowly the frame took shape infront of the massive crowd that was keen to be part of the big occasion.

I'm really still amazed that no one was injured during this consturction given the primitive methods used. I would have it no other way.

A big thanks to Briggsy and Sheers who turned up to work on the Saturday to get things moving. A special mention to Briggsy for falling off the first ladder he climbed up, once I told him there was no work cover he dusted himslef off and got on with it. This did however mean I needed to send the finance minister off for more supplies to enusure our thirst was satisfied at the end of the day.

The end result is the frame was completed by Saturday evening in readiness for the sheeting and roofing.

Start at the Start

Thursday night rolled around quite quickly and before I knew it I was standing in my driveway with a lot of steal and very little idea of how it fits together. Re-inforcements had been flown in and it was time to get down to business.

I first had to induct our two new employees to site, and with any new employees to a construction site there comes an initiation. Dale was sent off to Mitre 10 to pick up a can of Red and White stripped paint while Hobie was made to work naked for the first hour. I actually think that he enjoyed this time and you will see the photo below of Hobie performing the acent Budhist 'site blessing' by rubbing his bottom into the dirt.

Contstuction was slow to begin with as corners were measured and measure again. However, come lunch time on the first day we were appling the screws to the first column - This honor went to the finance minister.

As the Dazzler and myself worked on decreasing the pile of steal in the driveway we were well supported all day. Hobie was always on hand to pass any tools when required. Although I would like to think the first day was all smooth sailing the build team did come across some challenges, the below image shows the teamwork and communication that was evident as the frame took shape.

This discussion was one of many concerning the placement of column plates. Interestengly you will notice the five different size ratchet pieces on the footing, seems strange considering there was only ever one size of bolt that was used for all ten footings. I believe the answer is in the below picture.

You will notice the carlton draught stubbies in the top and bottom of the picutre, clearly the OH&S rep was not working this day!!

All in all a fantastic first day on the job with all 10 uprights in position and the back rafters raised. Massive praise to the Dazzler for his expertise - for his reward I think I'll give him one more beer.

I first had to induct our two new employees to site, and with any new employees to a construction site there comes an initiation. Dale was sent off to Mitre 10 to pick up a can of Red and White stripped paint while Hobie was made to work naked for the first hour. I actually think that he enjoyed this time and you will see the photo below of Hobie performing the acent Budhist 'site blessing' by rubbing his bottom into the dirt.

Contstuction was slow to begin with as corners were measured and measure again. However, come lunch time on the first day we were appling the screws to the first column - This honor went to the finance minister.

As the Dazzler and myself worked on decreasing the pile of steal in the driveway we were well supported all day. Hobie was always on hand to pass any tools when required. Although I would like to think the first day was all smooth sailing the build team did come across some challenges, the below image shows the teamwork and communication that was evident as the frame took shape.

This discussion was one of many concerning the placement of column plates. Interestengly you will notice the five different size ratchet pieces on the footing, seems strange considering there was only ever one size of bolt that was used for all ten footings. I believe the answer is in the below picture.

You will notice the carlton draught stubbies in the top and bottom of the picutre, clearly the OH&S rep was not working this day!!

All in all a fantastic first day on the job with all 10 uprights in position and the back rafters raised. Massive praise to the Dazzler for his expertise - for his reward I think I'll give him one more beer.

Tuesday, March 8, 2011

Excavation and Footings

Don the digger was called in and with the help of a Laser Level a 37 hour job with a shovel and wheel barrow was turned into 1.5 hours for a cost of $165 – the best $165 I’ve spent thus far on the build.

End result being a nice flat bit of dirt perfect for digging holes in - beautiful

Although this stage of the process was not without problems, the Mildrua floods cause a cease work period for 10 days - Bloody Unions not letting workers on a flooded site.

Well, when it comes to building something that you wish to stand the test of time it's important to have good foundations. And I will never question the foundations required for a good marriage.

However, I will question an engineer's decision for my shed to have footings 900mm deep. This is absolutely ridiculous. Thankfully the council felt the same way and turned a blind eye to the fact I may have come up 3mm short on a couple of the holes.

Notice the manditory footy shorts and chinese workboots when working with concrete.

The construction team was also lucky enough to provide a site tour for our finance department.

Poring shed footings can be fun for the first two holes, after this you will probably finding your self questioning why you would not just call in a concrete supplier and back a truck up.

All in all, 10 footings have now been pored and the shed is ready for construction.

Delivery of the shed is Thursday the 10th of March at 3:30pm, est time of completion is no earlier than 5pm Monday the 14th of March. Both Dale Husted and Hobie Husted will be inducted to site on Thursday afternoon and given all appropriate Personal Protected Equipment (PPE) before commencing construction.

Delivery of the shed is Thursday the 10th of March at 3:30pm, est time of completion is no earlier than 5pm Monday the 14th of March. Both Dale Husted and Hobie Husted will be inducted to site on Thursday afternoon and given all appropriate Personal Protected Equipment (PPE) before commencing construction.

The Shed Design and Location

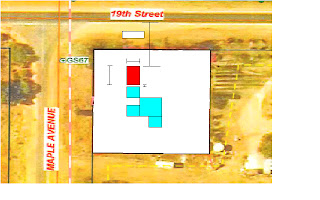

The shed design that will be constructed at 3764 Walnut Ave is a 6m X 9m X 2.7m shed with colorbond walls and zinc roof, this is to ensure the continuity of the two other site dwellings.

The shed will have two roller doors on the north facing side and 1 personal access door on the south face. Please see shed plans for more detail.

The location forced us to obtain a planning permit from the local council but due to the fact I had an insider this was completed in a record 234 days.

The shed will have two roller doors on the north facing side and 1 personal access door on the south face. Please see shed plans for more detail.

In The Begining

Embarking on such an important project it is important to build the right team. For this project the below team has been established:

Site Planning Officer: Simon Guthrie

Shed Design: Simon Guthrie

Site Excavation Technician: Simon Guthrie

Footing Construction: Simon Guthrie

Shed construction: Simon Guthrie

Floor construction: Simon Guthrie

Accounts Payable: Kate Guthrie

Site Security: Chilli

As you can see, I’ve kept the team reasonably small which allows for greater control, throughout the build I may be required to sub contract some of the labour intensive tasks out but this will only be to family members who work for beer, costs must be kept within budget.

The Boss - Simon Guthrie

Finance Department - Kate Guthrie

Site Security - Chilli

Site Planning Officer: Simon Guthrie

Shed Design: Simon Guthrie

Site Excavation Technician: Simon Guthrie

Footing Construction: Simon Guthrie

Shed construction: Simon Guthrie

Floor construction: Simon Guthrie

Accounts Payable: Kate Guthrie

Site Security: Chilli

As you can see, I’ve kept the team reasonably small which allows for greater control, throughout the build I may be required to sub contract some of the labour intensive tasks out but this will only be to family members who work for beer, costs must be kept within budget.

The Boss - Simon Guthrie

Finance Department - Kate Guthrie

Site Security - Chilli

Subscribe to:

Comments (Atom)